FlyThru operate a range of UAVs built or adapted specifically to client’s tasks. Each UAV has a different capability and are able to carry a range of sensors, standard RGB cameras, 360 and standard video, laser scanners and thermal to gather data for the client’s specific requirements and accuracies. The sensors feedback in real-time to the operator and inspector who can work along-side the team of pilots directing the inspection and even allowing them to take control of the camera to aim, zoom and capture previously unseen data safely and cost effectively.

CONFINED SPACE INSPECTION

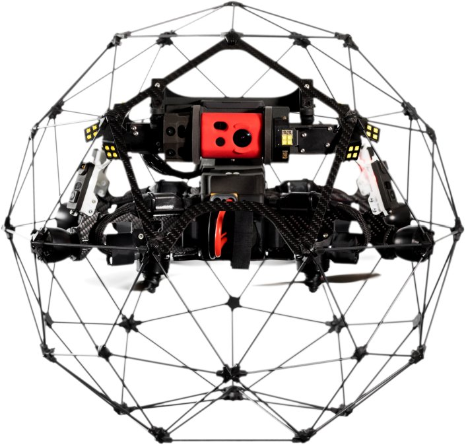

The safety of individuals at work is the primary objective of all companies and especially so when considering areas of limited access and danger. There are occasions when in order to preserve the safety of others that we need to collect data from these dangerous environments. Our team of experienced pilots use state of the art equipment including the Elios2 caged UAV to gain data in a safe and timely manner. FlyThru have performed inspections of culverts, adits, mines, inside structures and in the difficult to reach areas of standard structures where people and other UAVs simply could not go. The organisations we work for continue to be delighted at the data we collected and interpreted and the risks to people we have removed.

ELIOS 2

The Elios2 is capable of navigating through tight access points, through open windows, damaged roofs, pipes and culverts. The range of the system is excellent even within the GPS denied environments and although control is reliant on the strength of the radio control link data is obtained where others simply cannot go.

The primary data collection method from the Elios2 is 4K RGB video (with thermal overlay) and it is from this video still images are able be captured. Using other methods of survey to verify accuracy (specifically conventional laser-scanning) the data from the Elios2 can be interpreted and modelled to create accurate 3D point-cloud models to take a previously unimaginable snapshot of any area of interest safely.